Projects

This page provides more information on our projects. For additional questions about our projects, feel free to call us at (604) 813-0220 or email: cboucher@progressivesurveysolutions.com

Civil and infrastructure

Survey layout, Watay transmission line and substation, Northwestern Ontario

Survey layout/QC/Asbuilt, Site C 500KV Transmission Line Construction, Chetwynd, BC

Survey layout for guyed and self supported structures using helical piles. Provide accurate entry points for piles, monitor installation, mark pile cut off, assist welder during pile cap installation and shoe installation (self support). Build and maintain survey tracker to keep accurate record of survey/construction activities and quality control.

Check Survey surface and underground, Narrows Inlet, BC

Provided check survey of surface control at portal location and intake using RTK GPS raise breakthrough by Ramona Lake. Provided check survey of underground control network and adjusted control network. Wrote Technical report on procedures and baseline analysis results to confirm that the underground correlate with predicted surface breakthrough

Survey Management, QA and layout, Maritime Link, Stephenville, NL

Creation of structural survey layout files for 140km transmission line, adjustment to design based on finding in the field, communicating with clients for RFI, 3 survey layout crews. Management of other survey crews originally selected by client. Data management for Quality Assurance. Sag layout assistance on complex sections. Volume calculation for footings.

Survey layout and engineering support, TL267, Clarenville, NL

Provide 2 survey crew for layout of rock footing on self supported tower. Created layout in DXF format for quick layout and edit in the field with all options for leg extensions. Assistance on quantities calculation for payment. Asbuilt for Quality Assurance. Assisting engineering on guy wire calculation based on survey observations.

Land development and layout services, Chilliwack, BC

Provide earthwork layout and as built plans on utilities for municipal layout and land development on a variety of subdivisions in Chilliwack. Manipulate geospatial data for architects and civil engineers to work on similar datum. Volume Calculation, topographic survey (before and after excavation).

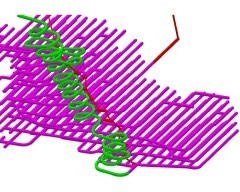

Sag layout, ILM Transmission Line, Chilliwack, BC

Construction Survey Management, NTL Extension, Iskut, BC

Management of all survey personnel and data on 95km 287KV Northwest Transmission Line Extension from Bob Quinn to Tatogga in British Columbia. Progressive Survey Solutions was involved with terrain analysis, foundations recommendation and layout for Self-supported, guy wire and monopoles structures. PSS provided the necessary Request for Information data to engineers, as-built information, construction coordination advices, guy wire lengths, tracking sheets of different phases of construction, analysis spreadsheets, redline drafting plans, geotechnical CAD plans. PSS also surveyed the sag asbuilt to confirm clearance and quality assurance.

Survey Crew Chief Manager ILM Transmission powerline, Chilliwack, BC

Manager of surveying activities for foundation layout of BC Hydro ILM Transmission powerline from Merritt to Coquitlam. In charge of training survey subcontractors, dispatching surveyor to working sites, communicating with Foreman and Superintendent on progress, terrain analysis for design changes. Work on Helicopter sites and steep high elevation terrain carrying very high precision level of surveying. Helping coworker resolving surveying issue with equipment. Assisting meeting with Foreman and Superintendents for optimization of human resources on certain sites.

Commercial and Industrial

Construction Survey, LP Shakeline Mill expansion, Swan River, Manitoba

High Precision Survey, International Paper mill, Grande Prairie, Alberta

Survey initial location of pedestals and mechanical key component. Set control, layout anchor bolts, work with millwright to reinstall Lime Kiln on newly engineered frame and mechanical motors. Help iron workers setting structural support surrounding main frame. Very congested area during mill shutdown and incredibly high precision requirements on frame position.

Construction Survey, Neptune Bulk Terminal, North Vancouver, BC

Construction/Engineering survey layout services on port expansion, rail car dumper, and a variety of elevated conveyor systems. Building layout files, layout procedures, control network, prepour/post checks, dimensional checks, anchor bolts layout, piles layout, concrete and structural steel layout, underground utilities layout and locating. Management/training of new hires and subcontractors

Construction Survey, Natural Gas distribution station, Vancouver, BC

Construction/Engineering survey layout services and data management for concrete, steel, pipes, civil, electrical components of large diameter pipe natural gas distribution site construction at Woodland and 2nd avenue. Set survey control network for entire project, confirm set back and geometry based on physical evidence provided by client, active layout throughout the entire construction, asbuilt documentation for return package.

Construction/Survey Layout, Trillium Living, Surrey, BC

Construction/Survey layout of 4 level 81 units condo with underground parking lot. Subgrade, columns, concrete slab, concrete structural wall and pour height layout. Pre pour check on rebar location, embedded plates, bolt patterns, void forms. Grid line, curbs, deck layout on main floor. Detailing in CAD making cheat sheets plan for concrete workers.

Concrete survey layout, Canadian High Arctic Research Station, NU

Concrete/Steel layout, Women and Children Hospital, Vancouver, BC

Underground training, scheduling, concrete and structural steel layout, Forrest Kerr Hydro Project, BC

Software training for underground surveyor. 3D modeling of underground aspect of excavation for better understanding of workflow with underground worker. Scheduling of final underground excavation for Powerhouse. Structural concrete layout of river intake on surface and structural steel layout at powerhouse underground. Quality control and monitoring of structural concrete and steel. Bridge and road layout.

Construction layout and Quality Control, Mayo B Tunnel Hydro project, Yukon

Progressive Survey Solutions took part in laying out the horizontal and vertical alignment of a 400m long tunnel that tie-in to an existing tunnel underground. While laying out and reporting to the designers and engineering staff, Progressive Survey Solutions also take care of the quality control and keep track of the cost of operation for the undergound portion of the project. Current tasks involve blast pattern design, blast pattern layout, alignment layout, volume calculations, inventory of explosives used, monitoring of deformation inside the tunnel.

Mining

Underground Survey and mine technician duty, Amaruq, Baker Lake, NU

Provided mine technician duties during staff transition. Provided plans and documentation for site inspection, underground layout, ventilation survey, 3D scanning workflow, design concrete pad and concrete bulkhead, inventory of underground supplies, yard and seacan organization for future supplies coming from barge, portal concrete footing design and layout.

Underground 3D scanning and Underground /Surface Control network, Premier Mine, Stewart, BC

Site vistit with client and consultant, Survey control network on 2 levels, 3D scanning of one level, GPS Static control survey on surface for future construction, site survey of a few features of interest on surface. Return consisted of CAD files of 3D drifts, point cloud and control network. Permitting work on phase one of bulk sample application with drafting and quantity calculations.

Underground Control Network/Training, Snip Mine, Bob Quinn, BC

Provided new survey control station to 7 level for upcoming drilling program, layout diamond drillhole foresight and backsight. Trained geologist and engineer on site how to use rental equipment to survey dip/azimuth and collar. Provided simplified plan view map of each drilling level with associated survey control and design DDH collar.

Construction Survey/Planning Services, Bonanza Ledge, Wells, BC

Supply permitting data in mapping format, complete survey layout and mapping services for surface earthwork, topography, utilities, structural, volume calculation, design and consultation. Provide underground layout, mapping, planning, calculation, CAD files, issue drive layout plans to underground crew.

Underground Check Survey, Prairie Creek, NWT

Check survey conducted from surface to underground tunnel to provide accurate survey control for future development. Produce mapping data for drilling permit. Documented all survey control on one geodetic datum as ask per client request.

Underground Check Survey, Brucejack Mine, BC

Check survey conducted from surface to underground tunnel to provide accurate survey control for future development such as conveyor tunnel to mill alignment, crusher and underground engineered ramp development. Produced report for Pretivm Resources with coordinates adjustment on newly installed survey control with survey methodology and results analysis.

Underground Survey layout and CAD, Brucejack mine, BC

Provided underground layout for main ramp, surveyed geology features for geology department, produce CAD plan of asbuilt of tunnel, reduce overbreak in tunnel by 25% by assisting jumbo drill operator and show them the asbuilt on tunnel face before jumbo setup to correct for adjustment.

Survey layout and monitoring Rocanville Shaft #2 extension, Rocanville, Saskatchewan

Survey layout and reporting on production of production of shaft #2 using non blasting technique under existing operational shaft. Daily survey monitoring of steel structure on existing shaft to assure safety of worker below. Reporting to engineering group at PCS the shifting trend of steel structure. Quality control and reporting with survey check on survey layout done by other contractor for ore bins rebar layout and also check elevation in headframe.

Underground surveying, Plan Preparation, Monthly production reports, Wolverine Mine, Yukon

In charge of underground survey layout and mapping of 15 active headings. Cut and paste method, ventilation raise and engineered ramp layout type surveying, month end production report for mining contractor. Ensure that all underground work complies to Yukon health and safety mine act. Training of company hired surveyor for general flow of layout scheduling for optimization of time spent underground. Plan preparation for monthly payments of mining contractor.

Underground Survey Training, Mine Planning, and Consulting, Mt Polley Mine, Likely, BC

Progressive Survey Solutions provides training to engineering and survey staff at the Mt Polley mine. Producing mine layout plans that underground miners use to stay on line and grade for their ramp and susequent mining levels. Also PSS assist the technical team at Mt Polley with mine planning software installation and training to produce 2D and 3D plans, sections, inventory...

Underground Optimization Mine Plan Design, Kwanika Property, North of Fort St James, BC

Underground design for ore body that was planned to be mined from surface. Ramp, sublevels, ventilation, and escape way were all designed with respect to BC Mine Act regulations. The goal of this design was to assist Engineers from Moose Mountain Technical Services (MMTS) optimizing the resource extraction at a lower cost with less dilution at a faster rate than the initial giant pit design. The association with MMTS expertise with mining cost and Progressive Survey Solutions expertise with Underground design was a success and potentially will grow to further projects.

Surveying, Mapping and Planning at Wingdam Mine, Quesnel, BC

The new ownership at the Wingdam mine, Quesnel, BC, wanted to get their project started with the most comprehensive engineering and mapping of their property. Along we came and assembled all the historical available data and added our own survey data by RTK GPS and Total Station to build a 3D model of the underground and surface. In a very short time the new ownership was able to use this set of data to promote the project to a wide range of investors. Progressive Survey Solutions also supply the necessary maps for the completion of their NI 43-101. We supplied all the mine plans and surveying for exploration drifting (Underground tunnelling) using a very unique horizontal freezing crosscut drift design through sedimentary clay, exploration drilling, and bulk tonnage permit.

Underground Bulk Sample Surveying/Planning, Meliadine, Rankin Inlet, Nunavut

The overall services offered by Progressive Survey Solutions improved dramatically the decision making in the Geology department for the whole duration of the Underground bulk sample. We offered grade layout, mine planning, underground survey control, 3D mapping and layout plans for miners, reconciliation stockpile volume of crushed ore. Progressive Survey Solutions also made some slashing plans and recommendations for larger underground equipment access. We provided a check survey with accurate underground control for the next phase of development. We left the client with more data in less than 2 months than what they produce in the last 3 years.

Construction and Drilling Coordination, Silvertip property, BC

Progressive Survey Solutions provided access route and location of drill hole at Silvertip mountain in Northern BC. We also coordinated the construction of the access road and drill pad throughout the duration of the 2010 exploration program on surface. Progressive Survey Solutions provided plans and maps to help the geologists making decision on future locations to explore.

Ruddock Creek Survey Layout and Volume calculation, Clearwater, BC

Our team surveyed the entire underground workings, built a 3D model and calculated the underground volumes in order to confirm previous work completed and set control points for future surveys. We are currently laying out and mapping the exploration drift, remucks, sumps, safety bays, drill stations... Progressive Survey Solutions also drafted the electrical diagram for submission to Ministry of Energy, Mines and Petroleum Resources.